The Monitoring Experts

Case Studies

The Monitoring Team is pleased to provide several case study examples of customers who have adopted one or more of Progressive’s monitoring products to make improvements to their manufacturing operations.

Impact of Real Time Data with Integrated Systems

COMPANY: Global Automotive Tier 1

CHALLENGE: Inefficient production and preventive maintenance management due to disparate manual systems, lack of visibility, and poor communication.

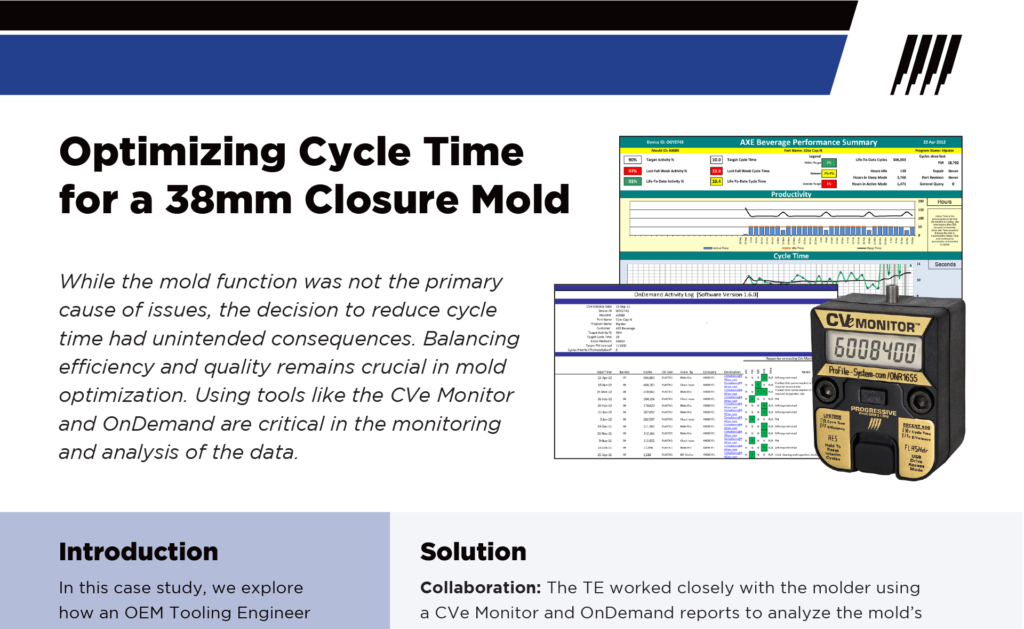

Optimizing Cycle Time for a 38mm Closure Mold

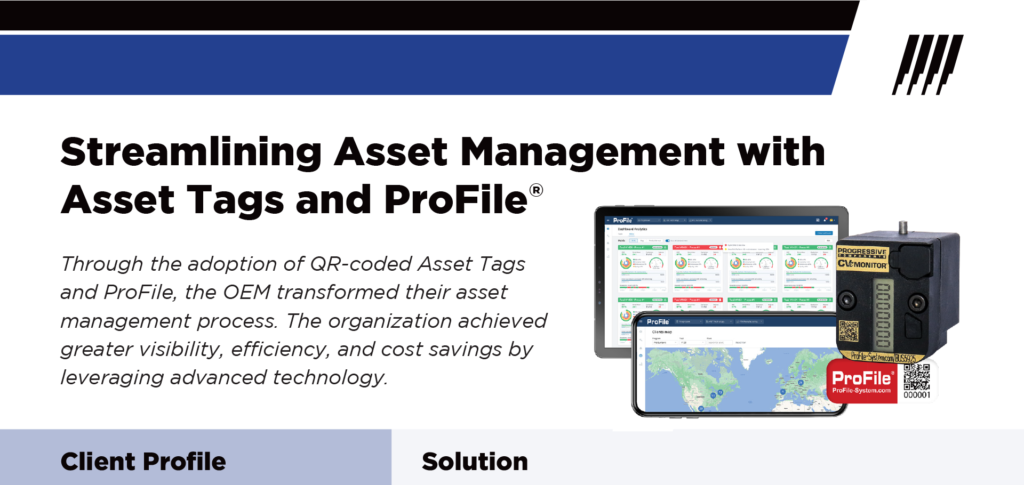

Streamlining Asset Management with Asset Tags and ProFile®

COMPANY: Global Medical OEM

CHALLENGE: Managing 1000+ assets across 15+ suppliers with little visibility and frequent travel for audits.

SOLUTION/RESULTS: Through the adoption of QR-coded Asset Tags and ProFile, the OEM transformed their asset management process. The organization achieved greater visibility, efficiency, and cost savings by leveraging advanced technology.