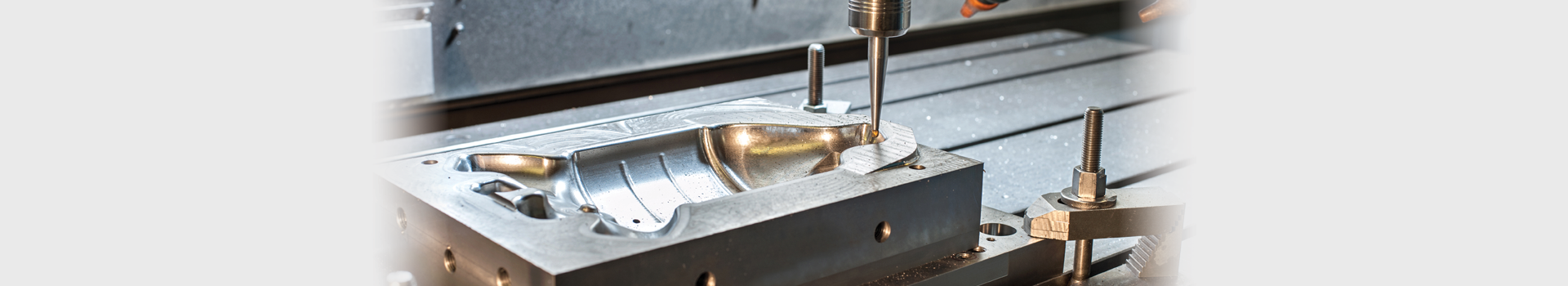

The Monitoring Experts

Your Challenges

- The exact location of your molds, dies, and other physical assets are.

- How they are being maintained.

- How productively they’re used.

- Asset tracking and maintenance management done by hand with clipboards and spreadsheets.

- Data gathered from various systems that don’t interface with one another.

- Scheduling in silos, no cross-functional communication and access.

- Travel to plants and suppliers’ plants.

- Manual translation of data.

It’s long been a difficult challenge, but now ProFile makes it easy and affordable.

- OEMs

Do you know where your manufacturing assets are located globally?

Do you find value in REAL-TIME visibility into the performance and maintenance of your manufacturing assets?

Can you access and share critical drawing and qualification documents?

How do you verify your supply chain is adhering to your preventative maintenance requirements?

How do you manage programs across multiple suppliers?

Is your asset tracking and maintenance management done by hand with clipboards and spreadsheets?

- Mold Builders

Do you have a system in which regular preventative maintenance events are recommended, tracked and logged?

Could you benefit from increased visibility in preventative maintenance schedule adherence?

Could you benefit from having a centralized location where files are able to be shared globally?

- Stampers

Are you tracking your punches per minute?

Are you losing profits when your cycle time standards deviate?

Do you have a system that alerts you when a downtime event occurs?

Would a stamping focused monitoring system add value to your operation?

- Injection Molders

How do you manage your molding assets today?

Could you pass a tooling audit?

Are you missing preventative maintenance events?

Do you monitor and take action when critical KPI metrics deviate from their standards?

How do you manage tooling work orders?